High-Quality Pcb Assembly Frame: A Complete Guide for Assembly

By:Admin

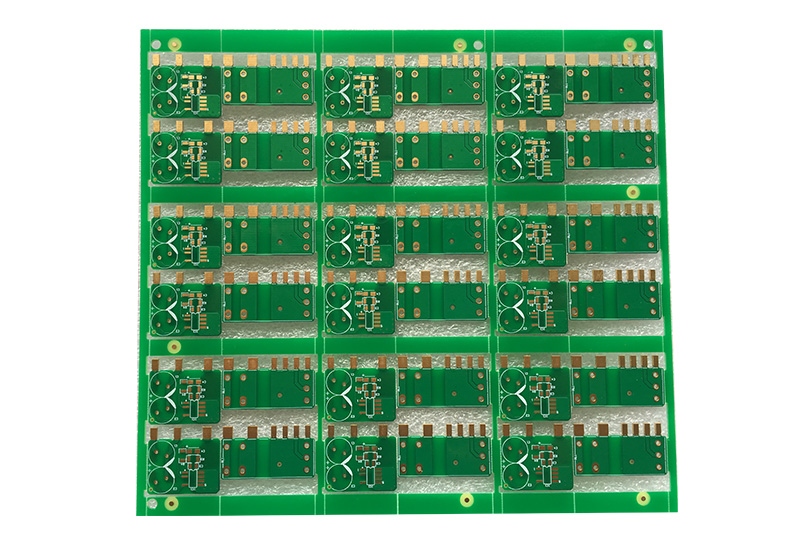

The new PCB assembly frame boasts a number of advanced features that set it apart from traditional frames on the market. With a focus on precision and reliability, the frame has been designed to ensure the accurate placement and soldering of components onto PCBs. This level of precision is crucial in the assembly process, as any inaccuracies can result in faulty or malfunctioning PCBs.

In addition to its precision, the assembly frame also offers a high level of flexibility, allowing for the efficient assembly of PCBs of varying sizes and complexities. This versatility is important for [Company Name]'s clients, as it enables them to streamline their production processes and reduce turnaround times.

The team at [Company Name] has also incorporated advanced automation technology into the new frame, further enhancing its efficiency and accuracy. This automation not only improves the speed of the assembly process but also eliminates the potential for human error, resulting in consistently high-quality PCBs.

[Company Name] has always been committed to staying at the forefront of technological advancements in the PCB assembly industry, and the development of this new frame is a testament to that commitment. By investing in research and development, the company has been able to consistently improve its capabilities and offer its clients the most advanced and reliable solutions on the market.

In addition to the new assembly frame, [Company Name] provides a comprehensive range of PCB assembly services. From prototype assembly to full production runs, the company has the expertise and resources to meet the needs of clients across various industries, including automotive, telecommunications, and consumer electronics.

The company's state-of-the-art facilities and advanced equipment allow for the efficient and cost-effective production of high-quality PCBs. Moreover, [Company Name] prides itself on its experienced team of engineers and technicians, who work closely with clients to ensure their specific requirements are met at every stage of the assembly process.

Furthermore, [Company Name] places a strong emphasis on quality control, conducting rigorous testing and inspection procedures to guarantee the reliability and performance of the assembled PCBs. This commitment to quality has earned the company a reputation as a trusted and preferred partner for PCB assembly among its clients.

With the introduction of this new assembly frame, [Company Name] is poised to further solidify its position as a leader in the PCB assembly industry. The company's dedication to innovation and excellence continues to drive its success, and it remains at the forefront of providing cutting-edge solutions to its clients.

In conclusion, the launch of the new PCB assembly frame represents a significant milestone for [Company Name] and further demonstrates its commitment to delivering the highest standards of quality and efficiency in PCB assembly. As the company continues to push the boundaries of technological advancement, clients can expect even greater capabilities and reliability in their PCB assembly requirements.

Company News & Blog

Effective PCB Design Methods for Power Electronics

Power Electronics PCB Design: Elevating Performance and EfficiencyIn our fast-paced and dynamic world, the demand for efficient and high-performing power electronics has become increasingly essential. From renewable energy systems to electric vehicles, these electronics play a crucial role in powering the technologies that drive our modern society. Behind the scenes, printed circuit board (PCB) design is at the heart of ensuring the optimal performance and reliability of power electronics.One company that has been leading the way in this domain is {}. With a strong focus on innovative PCB design solutions, {} has consistently delivered cutting-edge technology that has set new benchmarks in the industry. Their expertise in power electronics PCB design has enabled them to develop solutions that are not only powerful and efficient but also reliable and sustainable.One of the key aspects of {}'s PCB design services is their commitment to customized solutions. They understand that every application has unique requirements, and their team of experienced engineers works closely with clients to develop tailored designs that address specific needs. Whether it's designing PCBs for high-power applications or for environments with stringent operating conditions, {} has the expertise to deliver robust and efficient solutions.The company's emphasis on research and development has been instrumental in driving innovation in power electronics PCB design. They continuously invest in state-of-the-art technology and equipment to stay at the forefront of the industry. This commitment to innovation has led to the development of PCB designs that offer improved performance, higher efficiency, and greater reliability.In addition to their technical expertise, {} also places a strong emphasis on sustainability in their PCB design processes. They are dedicated to developing eco-friendly solutions that minimize the environmental impact without compromising on performance. By leveraging their extensive knowledge in materials and manufacturing processes, {} is able to offer PCB designs that are not only energy-efficient but also contribute to the overall sustainability of the power electronics industry.One of the notable achievements of {} in the power electronics PCB design space is their contribution to the advancement of renewable energy systems. Their innovative designs have been instrumental in enhancing the performance and efficiency of solar inverters, wind turbine controllers, and energy storage systems. By optimizing the power electronics at the heart of these renewable energy technologies, {} has played a significant role in driving the transition towards a more sustainable energy landscape.Moreover, {}'s PCB design solutions have also found applications in the rapidly growing electric vehicle (EV) industry. As the demand for electric vehicles continues to rise, the need for high-performance and reliable power electronics becomes increasingly critical. {} has been at the forefront of developing PCB designs for EV powertrains, battery management systems, and on-board chargers, contributing to the acceleration of the electric mobility revolution.With a proven track record of delivering exceptional PCB design solutions, {} has earned the trust of major players in the power electronics industry. Their commitment to quality, innovation, and sustainability has positioned them as a leading provider of power electronics PCB design services.As the demand for efficient and high-performing power electronics continues to soar, the role of PCB design in shaping the future of this industry becomes increasingly significant. With {}'s dedication to pushing the boundaries of innovation, it is poised to play a pivotal role in driving the next wave of advancements in power electronics technology.

Understanding the Function and Benefits of Passive Crystal Oscillators

Passive Crystal Oscillator: The Future of Precision Timekeeping and Frequency ControlIn today's world, precision timekeeping and frequency control are crucial in a wide range of applications, including telecommunications, navigation systems, medical devices, and many more. Companies are constantly looking for advanced solutions to meet the increasing demand for accuracy and stability in their products. This is where Passive Crystal Oscillator technology comes into play. {Company Name}, a leading provider of electronic components and solutions, has recently developed an innovative Passive Crystal Oscillator that promises to revolutionize the way precision timekeeping and frequency control are achieved in various industries. The company, known for its expertise in designing and manufacturing high-quality electronic components, has once again proven its commitment to innovation and excellence with this groundbreaking technology.So, what exactly is a Passive Crystal Oscillator and what makes it stand out from traditional solutions? Unlike traditional crystal oscillators, which require an external power source to operate, Passive Crystal Oscillators are entirely self-sustaining, making them highly reliable and energy-efficient. This unique feature makes them an ideal choice for battery-powered devices and applications where power consumption is a critical factor.The Passive Crystal Oscillator developed by {Company Name} offers unparalleled frequency stability and accuracy, making it suitable for a wide range of critical applications. With its advanced design and manufacturing process, the oscillator provides excellent performance in terms of temperature stability, aging characteristics, and low phase noise. This makes it an ideal solution for demanding applications where precision timing and frequency control are essential.One of the key advantages of {Company Name}'s Passive Crystal Oscillator is its compact and low-profile design, which allows for easy integration into various devices and systems. This makes it an attractive choice for manufacturers looking to reduce the size and weight of their products without compromising on performance. Furthermore, the oscillator's robust construction and high shock and vibration resistance make it suitable for use in harsh operating environments, further expanding its potential applications.It is worth noting that {Company Name} has a strong track record of delivering high-quality electronic components to a wide range of industries, including aerospace, automotive, industrial, and consumer electronics. The company's commitment to innovation and excellence has earned it a reputation as a trusted partner for companies seeking advanced electronic solutions. With the introduction of the Passive Crystal Oscillator, {Company Name} continues to demonstrate its dedication to pushing the boundaries of technology and providing industry-leading solutions to its customers.The potential impact of {Company Name}'s Passive Crystal Oscillator in the market is significant. With its superior performance, reliability, and energy efficiency, the oscillator has the potential to become the new standard in precision timekeeping and frequency control. It is expected to open up new possibilities for advancements in various industries, enabling companies to develop innovative products with improved performance and efficiency.As the demand for precision timekeeping and frequency control continues to grow, companies are increasingly turning to advanced solutions such as Passive Crystal Oscillators to meet their requirements. {Company Name}, with its proven expertise and commitment to innovation, is well-positioned to lead the way in this rapidly evolving field. With its new Passive Crystal Oscillator technology, the company is set to shape the future of precision timing and frequency control, providing industry-leading solutions that redefine the standard for performance and reliability.In conclusion, the introduction of {Company Name}'s Passive Crystal Oscillator represents a significant milestone in the field of precision timekeeping and frequency control. With its advanced technology, superior performance, and wide-ranging potential applications, the oscillator has the potential to revolutionize the way companies approach precision timing and frequency control. {Company Name} continues to demonstrate its leadership in electronic component innovation, providing industry-leading solutions that drive advancements across various sectors.

Advanced Wave Soldering: What You Need to Know

Smd Wave Soldering is a cutting-edge technology that has revolutionized the electronics manufacturing industry. The process involves the use of a wave soldering machine to meticulously solder surface mount devices (SMDs) onto printed circuit boards (PCBs), ensuring a high level of precision, efficiency, and reliability. One company that has been at the forefront of this innovative technology is {}.{} is a leading provider of advanced electronics manufacturing solutions, with a strong focus on SMD wave soldering. The company's expertise and commitment to excellence have made them a trusted partner for businesses looking to streamline their manufacturing processes and achieve superior results.With a dedication to research and development, {} has continuously pushed the boundaries of what is possible in electronics manufacturing. Their SMD wave soldering machines are equipped with state-of-the-art technology, including precise flux deposition, preheating capabilities, and nitrogen inerting for improved soldering quality. These features not only ensure a high level of accuracy and consistency but also contribute to reducing manufacturing defects and enhancing overall product performance.{}'s SMD wave soldering machines are designed to handle a wide range of PCB sizes and configurations, making them ideal for a variety of applications across industries such as automotive, medical, aerospace, and consumer electronics. This versatility, combined with the machines' high throughput and efficiency, has made {} a top choice for businesses seeking to streamline their production processes and stay ahead of the competition.In addition to their cutting-edge technology, {} is known for their exceptional customer service and extensive support network. From initial consultation and installation to ongoing maintenance and training, the company is committed to providing comprehensive assistance to their clients every step of the way. This commitment to customer satisfaction has earned {} a strong reputation in the industry and made them a preferred partner for businesses worldwide.As the demand for high-quality electronics continues to rise, {} remains at the forefront of the industry, continuously innovating and advancing their SMD wave soldering technology to meet the evolving needs of their clients. With a steadfast dedication to quality, efficiency, and customer satisfaction, {} is poised to continue leading the way in the electronics manufacturing industry.In conclusion, SMD wave soldering technology has revolutionized the electronics manufacturing industry, and {} has been a driving force behind this transformation. With their advanced machines, unwavering commitment to excellence, and exceptional customer support, {} has established itself as a trusted partner for businesses seeking to achieve superior results in their electronics manufacturing processes. As the industry continues to evolve, {} remains at the forefront, continuously pushing the boundaries of what is possible and setting new standards for quality and innovation.

How to Use a PCBA Stencil for Soldering Success

PCBA StencilPCBA stencils are an essential part of the printed circuit board assembly process. They are used to apply solder paste to the board, ensuring precise and accurate placement of components. This is crucial for ensuring the quality and performance of the final PCB assembly.In the fast-paced world of electronics manufacturing, efficiency and accuracy are key. That's why having the right tools and equipment is vital for success. PCBA stencils play a critical role in ensuring that every component is placed correctly, and the solder paste is applied accurately.By using a PCBA stencil, manufacturers can streamline the assembly process and achieve consistent results. This not only saves time but also improves the overall quality of the finished product. With the demand for high-quality electronics on the rise, having reliable and efficient tools like PCBA stencils is essential for staying competitive in the industry.{Company} is a leading supplier of PCBA stencils, offering a wide range of options to meet the diverse needs of electronics manufacturers. With years of experience in the industry, they understand the importance of precision and efficiency in PCB assembly. Their stencils are designed to deliver consistent and reliable performance, helping manufacturers achieve optimal results in their assembly process.{Company}'s PCBA stencils are made from high-quality materials and are precision-engineered to ensure accurate and reliable solder paste application. They offer a variety of stencil types, including stainless steel, nickel, and polymer stencils, to suit different manufacturing requirements. In addition, {Company} also provides custom stencil design services, allowing manufacturers to tailor their stencils to their specific needs.With a strong commitment to customer satisfaction, {Company} ensures that their stencils are manufactured to the highest standards. They invest in state-of-the-art technology and equipment to produce stencils that meet the strictest quality and performance requirements. This dedication to excellence has earned {Company} a reputation for being a trusted and reliable partner in the electronics manufacturing industry.In addition to providing high-quality stencils, {Company} also offers comprehensive support and technical assistance to help customers get the most out of their products. They understand the challenges of the PCB assembly process and are committed to providing solutions that improve efficiency and productivity. Whether it's guidance on stencil selection or assistance with custom design, {Company}'s team of experts is dedicated to helping customers achieve success in their manufacturing operations.As the demand for electronics continues to grow, the need for reliable and efficient PCB assembly solutions becomes increasingly important. {Company} is committed to meeting this demand by delivering top-quality PCBA stencils and exceptional customer support to electronics manufacturers around the world. With a focus on precision, performance, and customer satisfaction, {Company} is poised to remain a leader in the industry for years to come.

Essential Tips for Successfully Engineering PCBs

Pcb Engineering Expands its Business OperationsPcb Engineering, a leading engineering and manufacturing company, is expanding its business operations to better serve its growing customer base. With a focus on providing high-quality and innovative engineering solutions, Pcb Engineering is committed to meeting the needs of its clients in various industries, including automotive, aerospace, telecommunications, and medical devices.The company, headquartered in the United States, is known for its expertise in developing and manufacturing printed circuit boards (PCBs) and electronic components. With a team of highly skilled engineers and technicians, Pcb Engineering has built a reputation for delivering reliable and cutting-edge solutions to its clients.“We are thrilled to announce the expansion of our business operations,” said the CEO of Pcb Engineering. “As the demand for our products and services continues to grow, we are committed to investing in our infrastructure and expanding our capabilities to meet the needs of our clients. This expansion will allow us to increase our production capacity, improve our efficiency, and ultimately, better serve our customers.”In order to support its growth, Pcb Engineering has recently invested in state-of-the-art manufacturing equipment and technology. This investment will not only enhance the company’s production capabilities but also enable it to offer a wider range of engineering solutions to its clients.In addition to its investment in technology, Pcb Engineering is also expanding its workforce by hiring new talent across various functions, including engineering, manufacturing, quality control, and customer service. By bringing in new expertise and capabilities, the company aims to strengthen its position as a leading provider of engineering solutions in the industry.The expansion will also allow Pcb Engineering to further diversify its product offerings and enter new market segments. With a focus on continuous innovation, the company is committed to developing new and advanced engineering solutions that will address the evolving needs of its clients in different industries.Pcb Engineering’s commitment to quality and customer satisfaction has earned it a loyal and growing customer base. By expanding its business operations, the company aims to build on its strong reputation and further solidify its position as a trusted partner for engineering and manufacturing solutions.As part of its expansion plans, Pcb Engineering is also exploring opportunities to collaborate with strategic partners and suppliers to further enhance its capabilities and offerings. By leveraging the expertise and resources of its partners, the company aims to provide comprehensive and integrated solutions that meet the complex needs of its clients.With its expanded business operations, Pcb Engineering is well-positioned to capitalize on the growing demand for high-quality engineering solutions in the global market. The company’s dedication to innovation, quality, and customer satisfaction will continue to drive its growth and success in the industry.As Pcb Engineering continues to expand its operations, the company remains committed to upholding the highest standards of engineering excellence and customer service. With a focus on continuous improvement and innovation, the company is well-prepared to meet the evolving needs of its clients and deliver value-added solutions that drive their success.The expansion of Pcb Engineering’s business operations marks an exciting new chapter for the company as it seeks to further strengthen its position as a leading provider of engineering and manufacturing solutions globally. With its commitment to quality, innovation, and customer satisfaction, Pcb Engineering is poised for continued growth and success in the years to come.About Pcb EngineeringPcb Engineering is a leading engineering and manufacturing company that specializes in developing and manufacturing printed circuit boards and electronic components for various industries. With a focus on quality, innovation, and customer satisfaction, the company has built a strong reputation for delivering reliable and cutting-edge solutions to its clients. Headquartered in the United States, Pcb Engineering is committed to meeting the diverse needs of its customers by providing comprehensive and integrated engineering solutions.

BGA PCB Assembly: What You Need to Know for Your Electronic Devices

Bga Pcb Assembly Technology Revolutionizes Electronic ManufacturingIn today's rapidly advancing technological landscape, electronic manufacturing companies are constantly seeking innovative ways to enhance the quality and efficiency of their products. One of the most recent breakthroughs in this field is the introduction of BGA PCB assembly technology, which promises to revolutionize the way electronic components are manufactured and integrated into devices.BGA, or Ball Grid Array, is a type of surface-mount packaging used for integrated circuits. It has become increasingly popular in electronic manufacturing due to its high pin count and compact size, which allows for more complex and densely-packed electronic devices. The BGA packaging also offers better thermal and electrical performance, making it an attractive choice for manufacturers looking to enhance the reliability and performance of their products.One company at the forefront of this BGA assembly technology is {}. Established in 2005, {} has been a leading provider of electronic manufacturing services, specializing in PCB assembly, BGA assembly, and other advanced technologies. With a focus on delivering high-quality, cost-effective solutions, {} has become a trusted partner for companies seeking to elevate their electronic manufacturing capabilities.The integration of BGA assembly technology into {}'s manufacturing processes has significantly enhanced the company's ability to produce intricate and high-performance electronic components. By utilizing state-of-the-art BGA assembly equipment and expertise, {} is able to meet the increasing demands for smaller, more powerful electronic devices in a wide range of industries, including telecommunications, medical devices, aerospace, and consumer electronics.One of the key advantages of BGA PCB assembly is its ability to accommodate a higher density of interconnects, leading to a more compact and efficient design. This is particularly important in industries where space is a premium, such as mobile devices and wearables. By leveraging BGA assembly technology, {} is able to offer its clients sophisticated, miniaturized electronic components without compromising on performance or reliability.Furthermore, BGA assembly technology also allows for improved thermal management and electrical integrity, resulting in electronic components that are more durable and robust. This is critical in applications where electronic devices are subjected to harsh environmental conditions or prolonged use. {}'s expertise in BGA assembly ensures that the electronic components they manufacture meet the highest standards of quality and reliability, further solidifying their reputation as a leader in the electronic manufacturing industry.In addition to the technical benefits of BGA PCB assembly, {}'s adoption of this advanced technology has also resulted in streamlined manufacturing processes and reduced production costs. By optimizing the use of space and materials, {} is able to increase production efficiency and yield, ultimately delivering cost savings to their clients without compromising on quality.Looking towards the future, {} remains committed to staying at the forefront of electronic manufacturing innovation. With the continued advancement of BGA assembly technology and other cutting-edge manufacturing techniques, {} is well-positioned to meet the evolving demands of the industry and exceed the expectations of their clients.In conclusion, the integration of BGA PCB assembly technology has propelled {} to the forefront of electronic manufacturing, enabling them to produce smaller, more powerful, and more reliable electronic components. With a track record of innovation and excellence, {} continues to set the standard for electronic manufacturing services, meeting the needs of a diverse range of industries and driving the next wave of technological evolution.

Essential Tips for Using a PCB Stencil for Manufacturing

PCB Company Introduces Innovative Stencil for Enhanced PCB ManufacturingIn the world of PCB (Printed Circuit Board) manufacturing, precision and accuracy are crucial. With the advancement of technology, the demand for high-quality PCB stencils has increased significantly. To meet this demand, {Company Name}, a leading PCB manufacturing company, has introduced an innovative stencil for PCB use. This new stencil is designed to provide enhanced precision and efficiency in the PCB manufacturing process.The new stencil is a result of extensive research and development efforts by the {Company Name} team. It is created using high-quality materials and advanced manufacturing techniques to ensure superior performance. The stencil is designed to accurately transfer solder paste onto the PCB, enabling precise placement of surface mount components during the assembly process.One of the key features of the new stencil is its durability. It is made from a highly durable material that can withstand the rigors of the PCB manufacturing process, including multiple uses and cleaning cycles. This durability ensures that the stencil maintains its precision and performance over time, resulting in consistent high-quality PCB assemblies.In addition to durability, the new stencil also offers improved accuracy. Its advanced design and manufacturing process result in fine detail and precise openings, allowing for precise and consistent solder paste deposition. This level of accuracy is essential for the assembly of increasingly complex and miniaturized electronic components.Moreover, the new stencil is designed for ease of use. It is compatible with various PCB manufacturing equipment and processes, making it easy to integrate into existing manufacturing workflows. This compatibility ensures a smooth transition for PCB manufacturers who choose to adopt the new stencil for their operations.{Company Name} is renowned for its commitment to innovation and quality in PCB manufacturing. With the introduction of this new stencil, the company aims to further solidify its position as a leader in the industry. The innovative features of the new stencil demonstrate {Company Name}'s dedication to addressing the evolving needs of PCB manufacturers and supporting them in achieving outstanding results.In a statement, {Spokesperson Name}, {Title} at {Company Name}, expressed enthusiasm about the new stencil and its potential impact on the industry. "We are thrilled to introduce this advanced stencil for PCB use. It represents our ongoing efforts to push the boundaries of innovation in PCB manufacturing. We believe that this stencil will empower our customers to achieve new levels of precision and efficiency in their manufacturing processes."The introduction of the new stencil has already generated significant interest within the PCB manufacturing community. Several industry experts have lauded {Company Name} for its commitment to advancing the field of PCB manufacturing and providing practical solutions to industry challenges.In conclusion, the introduction of the innovative stencil for PCB use by {Company Name} represents a significant development in the PCB manufacturing industry. The new stencil's durability, accuracy, and ease of use are poised to make a positive impact on the efficiency and quality of PCB assembly processes. As the demand for high-quality PCBs continues to grow, {Company Name} is well-positioned to meet the needs of PCB manufacturers with its cutting-edge solutions.

Guide to Printed Circuit Boards: The Basics You Need to Know

Smt Printed Circuit Board Company Launches Innovative Technology in Electronics Manufacturing[Company Name], a leading name in electronic manufacturing, has recently unveiled their latest innovation in printed circuit board (PCB) technology. The company, known for its high-quality products and advanced manufacturing capabilities, has introduced a new line of surface mount technology (SMT) PCBs that are set to revolutionize the electronics industry.With the increasing demand for smaller, faster, and more efficient electronic devices, the need for advanced PCB technology has never been greater. [Company Name] has recognized this need and has invested heavily in research and development to bring their new SMT PCBs to the market.The new SMT PCBs from [Company Name] feature a number of innovative design and manufacturing techniques that set them apart from traditional PCBs. These include advanced routing and trace technology, high-density interconnects, and improved thermal management capabilities. These features make the SMT PCBs ideal for use in a wide range of electronic devices, including smartphones, tablets, wearables, and automotive electronics.One of the key advantages of the new SMT PCBs is their ability to accommodate smaller and more densely packed components. This allows electronics manufacturers to create smaller and more compact devices without compromising on performance or functionality. As a result, the new SMT PCBs from [Company Name] are expected to open up new possibilities for electronic design and innovation.In addition to their advanced design features, the new SMT PCBs also benefit from [Company Name]'s state-of-the-art manufacturing capabilities. The company's manufacturing facilities are equipped with the latest machinery and equipment, allowing them to produce PCBs with high precision and consistency. This ensures that the SMT PCBs meet the highest quality standards and are suitable for use in even the most demanding applications.The launch of the new SMT PCBs represents a significant milestone for [Company Name], as it demonstrates their commitment to staying at the forefront of technology in the electronics industry. With their extensive experience and expertise in PCB manufacturing, the company is well positioned to meet the needs of electronic manufacturers and designers looking for advanced and reliable PCB solutions.In a statement, [Company Name] expressed their excitement about the launch of the new SMT PCBs and their potential impact on the electronics industry. "We are proud to introduce our latest innovation in printed circuit board technology," said a spokesperson for [Company Name]. "Our new SMT PCBs are the result of extensive research and development, and we believe they will play a crucial role in shaping the future of electronic design and manufacturing."The announcement of the new SMT PCBs has been met with enthusiasm from the electronics industry, with many leading manufacturers expressing interest in incorporating the technology into their products. This is a testament to the reputation and credibility that [Company Name] has earned over the years as a reliable and innovative PCB manufacturer.As the demand for smaller, faster, and more efficient electronic devices continues to grow, the importance of advanced PCB technology cannot be overstated. With the launch of their new SMT PCBs, [Company Name] has once again demonstrated their ability to lead the way in electronic manufacturing and deliver cutting-edge solutions to their customers.The new SMT PCBs from [Company Name] are set to make a significant impact on the electronics industry, and their launch marks an exciting new chapter in the company's history. With their advanced design features and high-quality manufacturing, the SMT PCBs are poised to become a game-changer in electronic design and innovation. As electronic manufacturers and designers continue to push the boundaries of what is possible, [Company Name] is poised to be a key partner in their quest to create the next generation of electronic devices.

High Voltage Pressure Test: What You Need to Know

High Voltage Pressure Test Ensures Safety and Reliability of {}. As one of the leading companies in the electrical industry, {} is dedicated to providing high-quality products and services to its customers. With a focus on safety and reliability, the company recently conducted a high voltage pressure test to ensure the performance of its latest electrical equipment.The high voltage pressure test is a crucial part of the product development process, as it helps to identify any potential weaknesses or vulnerabilities in the electrical equipment. By subjecting the equipment to high levels of voltage and pressure, the test simulates real-world operating conditions and helps to ensure that the products meet the necessary safety and performance standards.With a strong commitment to quality and innovation, {} has invested heavily in state-of-the-art testing facilities and equipment. The company's testing laboratory is equipped with the latest technology and tools to conduct rigorous and thorough tests on its products.During the high voltage pressure test, the electrical equipment is subjected to extreme conditions to measure its performance and reliability. The test helps to ensure that the equipment can withstand high levels of voltage and pressure without compromising its safety or functionality. By conducting this test, {} can provide assurance to its customers that their electrical equipment is safe and reliable for use in various applications.The high voltage pressure test is just one of the many tests that {} conducts on its products to ensure their performance and safety. The company's rigorous testing procedures and quality control measures are designed to meet and exceed industry standards and regulations.In addition to the high voltage pressure test, {} also conducts a series of other tests, including insulation resistance test, dielectric strength test, and temperature rise test, to guarantee the reliability and safety of its electrical equipment. These comprehensive tests help to identify any potential issues or weaknesses in the products and ensure that they meet the highest quality standards.With its strong focus on safety and reliability, {} is committed to providing its customers with the highest quality electrical equipment that meets the strictest industry standards. By conducting thorough testing and quality control measures, the company can guarantee the performance and safety of its products, ensuring the satisfaction and trust of its customers.The high voltage pressure test conducted by {} is a testament to the company's dedication to providing safe and reliable electrical equipment. By investing in advanced testing facilities and equipment, {} demonstrates its commitment to quality and innovation, setting itself apart as a leader in the electrical industry.In conclusion, the high voltage pressure test conducted by {} is a critical step in ensuring the safety and reliability of its electrical equipment. With its state-of-the-art testing facilities and rigorous testing procedures, {} is committed to providing its customers with the highest quality products that meet the strictest industry standards. Through its dedication to quality and innovation, {} continues to set the standard for excellence in the electrical industry.

How to Flash STM32 Microcontroller: A Step-by-Step Guide

Flashing STM32 Microcontrollers: Cutting-Edge Technology at {Company Name}{Company Name} is proud to announce a groundbreaking development in the field of microcontroller technology. The company has successfully integrated the STM32 flashing feature into its range of microcontrollers, pushing the boundaries of innovation and paving the way for advanced applications in the electronics industry.The STM32 microcontroller series, developed by STMicroelectronics, is renowned for its high performance, low power consumption, and advanced feature set. With the addition of STM32 flashing, {Company Name} has further solidified its position as a leading provider of cutting-edge microcontroller solutions.The STM32 flashing feature is a crucial advancement that allows for the quick and efficient programming of STM32 microcontrollers. This technology significantly reduces development time and streamlines the production process, making it an invaluable tool for engineers and developers working on a wide range of applications, from IoT devices to industrial automation systems.By incorporating STM32 flashing into its microcontrollers, {Company Name} has demonstrated its commitment to staying at the forefront of technological advancements. This move not only enhances the company's product offerings but also demonstrates its dedication to meeting the evolving needs of its customers.{Company Name} has a long history of designing and manufacturing high-quality microcontroller solutions, and the addition of STM32 flashing further underscores its dedication to excellence. With a focus on innovation and customer satisfaction, the company has successfully established itself as a trusted partner for businesses seeking reliable and cutting-edge microcontroller solutions.In addition to its technical capabilities, {Company Name} prides itself on its commitment to customer support and collaboration. The company works closely with its clients to understand their specific project requirements and provide tailored solutions that meet their exact needs. With a team of experienced engineers and support staff, {Company Name} is well-equipped to assist customers at every stage of the design and implementation process.The integration of STM32 flashing into {Company Name}'s microcontroller lineup opens up new possibilities for businesses looking to develop advanced and efficient electronic devices. Whether it's enhancing the performance of existing products or creating new, innovative solutions, the inclusion of STM32 flashing provides a powerful tool that can drive the success of a wide range of projects.With a proven track record of delivering high-quality microcontroller solutions, {Company Name} is well-positioned to help businesses leverage the capabilities of STM32 flashing for their projects. The company's dedication to innovation, quality, and customer satisfaction makes it a trusted partner for companies looking to take their electronic products to the next level.As the electronics industry continues to evolve, {Company Name} remains committed to staying ahead of the curve and providing its customers with the latest and most advanced technologies. The incorporation of STM32 flashing into its microcontroller offerings is a testament to the company's ongoing dedication to innovation, and it further solidifies its position as a leader in the field of microcontroller solutions.In conclusion, the addition of STM32 flashing to {Company Name}'s microcontroller lineup represents a significant advancement that will benefit businesses seeking to develop cutting-edge electronic devices. With a focus on innovation, quality, and customer satisfaction, {Company Name} is well-equipped to help its clients capitalize on the potential of this groundbreaking technology. As the company continues to push the boundaries of what's possible in the field of microcontroller solutions, its dedication to excellence ensures that it will remain a trusted and reliable partner for businesses seeking to achieve success in the ever-changing world of electronics.