Best Practices for Multilayer PCB Design for Electronics

By:Admin

Headquartered in [location], Multiboard PCB has been consistently pushing the boundaries of technological advancements in the electronic manufacturing industry. With state-of-the-art facilities and a team of skilled professionals, the company has been able to stay ahead of the curve and meet the ever-evolving needs of its clients.

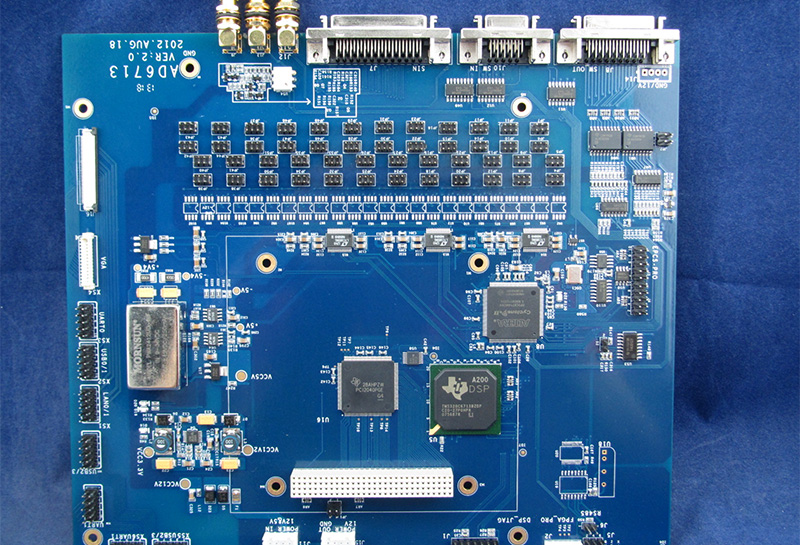

One of the most recent developments from Multiboard PCB is their new line of multilayer PCBs. These multilayer PCBs are designed to meet the complex demands of modern electronic devices, offering increased functionality and efficiency in a compact form factor. By leveraging advanced manufacturing techniques and rigorous quality control processes, Multiboard PCB has been able to create multilayer PCBs that offer unmatched reliability and performance.

The new multilayer PCBs from Multiboard PCB are ideal for a wide range of applications, including consumer electronics, automotive systems, medical devices, and industrial equipment. These PCBs are designed to support high-speed data transfer, low power consumption, and seamless integration with other electronic components, making them the perfect choice for cutting-edge electronic devices.

In addition to their new multilayer PCBs, Multiboard PCB has also been making strides in the development of flexible and rigid-flex PCBs. These innovative PCB solutions are designed to meet the growing demand for compact and lightweight electronic devices, offering enhanced flexibility and durability without compromising on performance.

Furthermore, Multiboard PCB has also been investing in research and development to explore new materials and manufacturing processes that will further enhance the performance and reliability of their PCB solutions. By staying at the forefront of technological advancements, the company is well-positioned to continue meeting the evolving needs of the electronics industry.

Multiboard PCB’s commitment to innovation and excellence has not gone unnoticed. The company has received accolades and recognition for its contributions to the electronics industry, further solidifying its position as a trusted and reliable partner for electronic manufacturers around the world.

As the demand for advanced PCB solutions continues to grow, Multiboard PCB is poised to play a pivotal role in shaping the future of the electronics industry. With their unwavering dedication to quality, innovation, and customer satisfaction, the company is well-prepared to meet the challenges and opportunities that lie ahead.

In conclusion, Multiboard PCB has proven itself to be a leader in the electronics industry, thanks to its commitment to delivering high-quality and innovative PCB solutions. With their new line of multilayer PCBs and ongoing investment in research and development, the company is well-positioned to continue exceeding the expectations of its customers and driving the industry forward.

Company News & Blog

Essential Tips for Using a PCB Stencil for Manufacturing

PCB Company Introduces Innovative Stencil for Enhanced PCB ManufacturingIn the world of PCB (Printed Circuit Board) manufacturing, precision and accuracy are crucial. With the advancement of technology, the demand for high-quality PCB stencils has increased significantly. To meet this demand, {Company Name}, a leading PCB manufacturing company, has introduced an innovative stencil for PCB use. This new stencil is designed to provide enhanced precision and efficiency in the PCB manufacturing process.The new stencil is a result of extensive research and development efforts by the {Company Name} team. It is created using high-quality materials and advanced manufacturing techniques to ensure superior performance. The stencil is designed to accurately transfer solder paste onto the PCB, enabling precise placement of surface mount components during the assembly process.One of the key features of the new stencil is its durability. It is made from a highly durable material that can withstand the rigors of the PCB manufacturing process, including multiple uses and cleaning cycles. This durability ensures that the stencil maintains its precision and performance over time, resulting in consistent high-quality PCB assemblies.In addition to durability, the new stencil also offers improved accuracy. Its advanced design and manufacturing process result in fine detail and precise openings, allowing for precise and consistent solder paste deposition. This level of accuracy is essential for the assembly of increasingly complex and miniaturized electronic components.Moreover, the new stencil is designed for ease of use. It is compatible with various PCB manufacturing equipment and processes, making it easy to integrate into existing manufacturing workflows. This compatibility ensures a smooth transition for PCB manufacturers who choose to adopt the new stencil for their operations.{Company Name} is renowned for its commitment to innovation and quality in PCB manufacturing. With the introduction of this new stencil, the company aims to further solidify its position as a leader in the industry. The innovative features of the new stencil demonstrate {Company Name}'s dedication to addressing the evolving needs of PCB manufacturers and supporting them in achieving outstanding results.In a statement, {Spokesperson Name}, {Title} at {Company Name}, expressed enthusiasm about the new stencil and its potential impact on the industry. "We are thrilled to introduce this advanced stencil for PCB use. It represents our ongoing efforts to push the boundaries of innovation in PCB manufacturing. We believe that this stencil will empower our customers to achieve new levels of precision and efficiency in their manufacturing processes."The introduction of the new stencil has already generated significant interest within the PCB manufacturing community. Several industry experts have lauded {Company Name} for its commitment to advancing the field of PCB manufacturing and providing practical solutions to industry challenges.In conclusion, the introduction of the innovative stencil for PCB use by {Company Name} represents a significant development in the PCB manufacturing industry. The new stencil's durability, accuracy, and ease of use are poised to make a positive impact on the efficiency and quality of PCB assembly processes. As the demand for high-quality PCBs continues to grow, {Company Name} is well-positioned to meet the needs of PCB manufacturers with its cutting-edge solutions.

High Voltage Pressure Test: What You Need to Know

High Voltage Pressure Test Ensures Safety and Reliability of {}. As one of the leading companies in the electrical industry, {} is dedicated to providing high-quality products and services to its customers. With a focus on safety and reliability, the company recently conducted a high voltage pressure test to ensure the performance of its latest electrical equipment.The high voltage pressure test is a crucial part of the product development process, as it helps to identify any potential weaknesses or vulnerabilities in the electrical equipment. By subjecting the equipment to high levels of voltage and pressure, the test simulates real-world operating conditions and helps to ensure that the products meet the necessary safety and performance standards.With a strong commitment to quality and innovation, {} has invested heavily in state-of-the-art testing facilities and equipment. The company's testing laboratory is equipped with the latest technology and tools to conduct rigorous and thorough tests on its products.During the high voltage pressure test, the electrical equipment is subjected to extreme conditions to measure its performance and reliability. The test helps to ensure that the equipment can withstand high levels of voltage and pressure without compromising its safety or functionality. By conducting this test, {} can provide assurance to its customers that their electrical equipment is safe and reliable for use in various applications.The high voltage pressure test is just one of the many tests that {} conducts on its products to ensure their performance and safety. The company's rigorous testing procedures and quality control measures are designed to meet and exceed industry standards and regulations.In addition to the high voltage pressure test, {} also conducts a series of other tests, including insulation resistance test, dielectric strength test, and temperature rise test, to guarantee the reliability and safety of its electrical equipment. These comprehensive tests help to identify any potential issues or weaknesses in the products and ensure that they meet the highest quality standards.With its strong focus on safety and reliability, {} is committed to providing its customers with the highest quality electrical equipment that meets the strictest industry standards. By conducting thorough testing and quality control measures, the company can guarantee the performance and safety of its products, ensuring the satisfaction and trust of its customers.The high voltage pressure test conducted by {} is a testament to the company's dedication to providing safe and reliable electrical equipment. By investing in advanced testing facilities and equipment, {} demonstrates its commitment to quality and innovation, setting itself apart as a leader in the electrical industry.In conclusion, the high voltage pressure test conducted by {} is a critical step in ensuring the safety and reliability of its electrical equipment. With its state-of-the-art testing facilities and rigorous testing procedures, {} is committed to providing its customers with the highest quality products that meet the strictest industry standards. Through its dedication to quality and innovation, {} continues to set the standard for excellence in the electrical industry.

How to Use a PCBA Stencil for Soldering Success

PCBA StencilPCBA stencils are an essential part of the printed circuit board assembly process. They are used to apply solder paste to the board, ensuring precise and accurate placement of components. This is crucial for ensuring the quality and performance of the final PCB assembly.In the fast-paced world of electronics manufacturing, efficiency and accuracy are key. That's why having the right tools and equipment is vital for success. PCBA stencils play a critical role in ensuring that every component is placed correctly, and the solder paste is applied accurately.By using a PCBA stencil, manufacturers can streamline the assembly process and achieve consistent results. This not only saves time but also improves the overall quality of the finished product. With the demand for high-quality electronics on the rise, having reliable and efficient tools like PCBA stencils is essential for staying competitive in the industry.{Company} is a leading supplier of PCBA stencils, offering a wide range of options to meet the diverse needs of electronics manufacturers. With years of experience in the industry, they understand the importance of precision and efficiency in PCB assembly. Their stencils are designed to deliver consistent and reliable performance, helping manufacturers achieve optimal results in their assembly process.{Company}'s PCBA stencils are made from high-quality materials and are precision-engineered to ensure accurate and reliable solder paste application. They offer a variety of stencil types, including stainless steel, nickel, and polymer stencils, to suit different manufacturing requirements. In addition, {Company} also provides custom stencil design services, allowing manufacturers to tailor their stencils to their specific needs.With a strong commitment to customer satisfaction, {Company} ensures that their stencils are manufactured to the highest standards. They invest in state-of-the-art technology and equipment to produce stencils that meet the strictest quality and performance requirements. This dedication to excellence has earned {Company} a reputation for being a trusted and reliable partner in the electronics manufacturing industry.In addition to providing high-quality stencils, {Company} also offers comprehensive support and technical assistance to help customers get the most out of their products. They understand the challenges of the PCB assembly process and are committed to providing solutions that improve efficiency and productivity. Whether it's guidance on stencil selection or assistance with custom design, {Company}'s team of experts is dedicated to helping customers achieve success in their manufacturing operations.As the demand for electronics continues to grow, the need for reliable and efficient PCB assembly solutions becomes increasingly important. {Company} is committed to meeting this demand by delivering top-quality PCBA stencils and exceptional customer support to electronics manufacturers around the world. With a focus on precision, performance, and customer satisfaction, {Company} is poised to remain a leader in the industry for years to come.

Guide to SMT Component Reels: What You Need to Know

[Company Name] Introduces New SMT Component Reel for Enhanced Efficiency[City, State], [Date] – [Company Name], a leading provider of electronic components and solutions, is proud to announce the release of their latest SMT component reel. This new product is designed to enhance efficiency and streamline the surface mount technology (SMT) process for manufacturers and engineers.The SMT component reel is an essential tool for electronic manufacturing as it allows for efficient and accurate placement of surface mount components onto printed circuit boards (PCBs). With the increasing demand for smaller and more complex electronic devices, the need for a reliable and high-performance SMT component reel has never been greater.The new SMT component reel from [Company Name] is built with precision and reliability in mind. It features a durable and lightweight design, making it easy to handle and transport on the manufacturing floor. The reel also comes with a high-capacity storage for SMT components, allowing for seamless and uninterrupted production processes.One of the key features of the new SMT component reel is its compatibility with a wide range of SMT components, including resistors, capacitors, and integrated circuits. This versatility makes it an ideal solution for manufacturers working with diverse product lines and custom electronic designs.In addition to its compatibility, the SMT component reel is designed for easy integration with automated pick-and-place machines. This seamless integration further enhances the efficiency and accuracy of the SMT process, ultimately improving the overall manufacturing output for our customers.[Company Name] is known for its commitment to quality and customer satisfaction, and the new SMT component reel is no exception. Each reel undergoes rigorous testing and quality assurance processes to ensure consistent and reliable performance in the most demanding manufacturing environments."We are excited to introduce our latest SMT component reel to the market," said [Spokesperson's Name], [Title] at [Company Name]. "This product is the result of our dedication to providing innovative and reliable solutions for our customers. We believe that the new SMT component reel will significantly improve the efficiency and productivity of electronic manufacturing processes, ultimately delivering greater value to our customers."As a leading provider of electronic components and solutions, [Company Name] is well-positioned to meet the evolving needs of the electronics industry. The introduction of the new SMT component reel further solidifies the company's commitment to delivering cutting-edge products and solutions that drive innovation and success for its customers.With the launch of the new SMT component reel, [Company Name] continues to demonstrate its expertise and leadership in the electronic components market. The company's dedication to quality, reliability, and customer satisfaction sets it apart as a trusted partner for manufacturers and engineers seeking high-performance solutions for their electronic manufacturing needs.

Ultimate Guide to Debugging Dotnet Tests for Improved Performance

In recent tech news, the latest version of Debug Dotnet Test was unveiled, promising new features and improvements to enhance the experience for developers using the platform. This update comes as a result of the company's ongoing commitment to providing top-notch tools for software development and testing.For those unfamiliar, Debug Dotnet Test is a widely-used platform that offers a comprehensive suite of testing and debugging tools for .NET applications. It has gained popularity among developers for its user-friendly interface and powerful features that streamline the testing process and improve overall code quality.The latest version of Debug Dotnet Test brings a host of new features aimed at further empowering developers and ensuring seamless testing and debugging of their applications. Some of the notable updates include enhanced support for automated testing, improved performance for large-scale projects, and expanded compatibility with various development environments.In addition, the update also introduces new debugging capabilities that allow for more efficient identification and resolution of issues within code. With these new features, developers can expect to see an increase in productivity and a reduction in the time spent on debugging and testing tasks.According to the company, the decision to prioritize these updates stemmed from a deep understanding of the challenges faced by developers when it comes to testing and debugging their applications. By actively listening to the feedback from their user community, the company was able to identify key areas for improvement and implement changes that directly address the needs of their user base.Furthermore, the company has reaffirmed its commitment to ongoing support and maintenance of the Debug Dotnet Test platform, ensuring that developers can continue to rely on it as a fundamental tool for their software development projects.With the release of the latest version of Debug Dotnet Test, the company has once again demonstrated its dedication to providing cutting-edge solutions that empower developers and streamline their workflow. By staying at the forefront of technological advancements and actively engaging with their user community, the company continues to solidify its position as a leader in the development tools market.As developers continue to navigate the complexities of modern software development, having reliable and feature-rich testing and debugging tools is essential. With the latest updates to Debug Dotnet Test, developers can look forward to a more efficient and productive testing process, ultimately leading to higher quality code and faster time to market for their applications.In conclusion, the latest version of Debug Dotnet Test represents a significant milestone in the ongoing evolution of the platform, bringing new and improved features that directly address the needs of developers. With its continued focus on innovation and user satisfaction, the company behind Debug Dotnet Test is well-positioned to support the ever-changing needs of the developer community and propel the future of software development forward.

Effective PCB Design Methods for Power Electronics

Power Electronics PCB Design: Elevating Performance and EfficiencyIn our fast-paced and dynamic world, the demand for efficient and high-performing power electronics has become increasingly essential. From renewable energy systems to electric vehicles, these electronics play a crucial role in powering the technologies that drive our modern society. Behind the scenes, printed circuit board (PCB) design is at the heart of ensuring the optimal performance and reliability of power electronics.One company that has been leading the way in this domain is {}. With a strong focus on innovative PCB design solutions, {} has consistently delivered cutting-edge technology that has set new benchmarks in the industry. Their expertise in power electronics PCB design has enabled them to develop solutions that are not only powerful and efficient but also reliable and sustainable.One of the key aspects of {}'s PCB design services is their commitment to customized solutions. They understand that every application has unique requirements, and their team of experienced engineers works closely with clients to develop tailored designs that address specific needs. Whether it's designing PCBs for high-power applications or for environments with stringent operating conditions, {} has the expertise to deliver robust and efficient solutions.The company's emphasis on research and development has been instrumental in driving innovation in power electronics PCB design. They continuously invest in state-of-the-art technology and equipment to stay at the forefront of the industry. This commitment to innovation has led to the development of PCB designs that offer improved performance, higher efficiency, and greater reliability.In addition to their technical expertise, {} also places a strong emphasis on sustainability in their PCB design processes. They are dedicated to developing eco-friendly solutions that minimize the environmental impact without compromising on performance. By leveraging their extensive knowledge in materials and manufacturing processes, {} is able to offer PCB designs that are not only energy-efficient but also contribute to the overall sustainability of the power electronics industry.One of the notable achievements of {} in the power electronics PCB design space is their contribution to the advancement of renewable energy systems. Their innovative designs have been instrumental in enhancing the performance and efficiency of solar inverters, wind turbine controllers, and energy storage systems. By optimizing the power electronics at the heart of these renewable energy technologies, {} has played a significant role in driving the transition towards a more sustainable energy landscape.Moreover, {}'s PCB design solutions have also found applications in the rapidly growing electric vehicle (EV) industry. As the demand for electric vehicles continues to rise, the need for high-performance and reliable power electronics becomes increasingly critical. {} has been at the forefront of developing PCB designs for EV powertrains, battery management systems, and on-board chargers, contributing to the acceleration of the electric mobility revolution.With a proven track record of delivering exceptional PCB design solutions, {} has earned the trust of major players in the power electronics industry. Their commitment to quality, innovation, and sustainability has positioned them as a leading provider of power electronics PCB design services.As the demand for efficient and high-performing power electronics continues to soar, the role of PCB design in shaping the future of this industry becomes increasingly significant. With {}'s dedication to pushing the boundaries of innovation, it is poised to play a pivotal role in driving the next wave of advancements in power electronics technology.

High-quality Printed Circuit Board Parts for Electronic Devices

Pcb Parts, a leading provider of high-quality electronic components, has recently announced the launch of their latest line of products that are set to revolutionize the electronic industry. The company, known for its commitment to excellence and innovation, has long been a trusted name in the field of electronic components. With this new line of products, Pcb Parts aims to further solidify its position as a market leader and provide its customers with the best solutions for their electronic needs.Founded in [insert year], Pcb Parts has quickly gained a reputation for delivering superior quality products and exceptional customer service. The company's extensive experience in the industry has allowed them to develop a deep understanding of their customers' needs and requirements, enabling them to consistently deliver innovative and reliable solutions. With a commitment to staying ahead of the curve and embracing the latest technological advancements, Pcb Parts has become a trusted partner for businesses and individuals looking for top-of-the-line electronic components.The new line of products from Pcb Parts encompasses a wide range of electronic components, including [insert specific products]. These products have been designed and produced using the latest technology and manufacturing processes, ensuring the highest level of quality and performance. Pcb Parts has always been dedicated to providing their customers with the best products on the market, and this new line is no exception. The company's team of skilled engineers and technicians have worked tirelessly to develop these products, and the result is a range of components that are durable, reliable, and efficient.One of the key features of the new line of products from Pcb Parts is their versatility. Whether customers are looking for components for consumer electronics, industrial machinery, or automotive applications, Pcb Parts has a solution to meet their needs. The company understands that each industry has its own unique requirements, and their products have been engineered to provide optimal performance in a wide range of applications. This versatility sets Pcb Parts apart from other providers in the industry and has made them a preferred choice for businesses across various sectors.In addition to the quality and versatility of their products, Pcb Parts is also committed to providing exceptional customer service. The company's team of dedicated professionals is always on hand to offer expert advice and guidance to their customers, helping them find the perfect solution for their specific needs. Pcb Parts understands that electronic components are a critical part of any project, and they strive to make the process of selecting and purchasing these components as smooth and seamless as possible.With the launch of this new line of products, Pcb Parts has once again demonstrated their commitment to excellence and innovation. The company's dedication to providing superior quality electronic components, combined with their exceptional customer service, has made them a trusted partner for businesses and individuals around the world. As technology continues to advance, Pcb Parts remains at the forefront of the industry, consistently delivering state-of-the-art solutions that meet the evolving needs of their customers.In conclusion, the launch of the new line of products from Pcb Parts marks an exciting development for the electronic industry. With their unparalleled commitment to quality, innovation, and customer service, Pcb Parts is set to continue leading the way in the electronic components market. Businesses and individuals looking for top-quality electronic components can trust Pcb Parts to provide them with the best solutions available.

High-Quality Printed Circuit Board Assembly Services - All You Need to Know

Printed Circuit Board Assembly (PCBA) is an essential part of electronic devices, and it plays a crucial role in the functionality of various electronic products. PCBA typically involves soldering various electronic components onto a printed circuit board, which is then used in devices such as smartphones, computers, and other electronic gadgets.{Company Name} is a leading manufacturer of PCBA, specializing in high-quality electronic assembly and manufacturing services. With a strong focus on innovation and technology, {Company Name} has built a reputation for delivering reliable and cost-effective PCBA solutions to a wide range of industries.Recently, {Company Name} announced the launch of its latest generation of PCBA, which features advanced technology and enhanced capabilities. The new PCBA is designed to meet the increasing demand for smaller, more powerful, and more energy-efficient electronics, offering customers a reliable and efficient solution for their electronic assembly needs.The new PCBA from {Company Name} incorporates the latest advancements in manufacturing technology, including state-of-the-art automated assembly equipment and advanced quality control processes. This allows {Company Name} to produce PCBA with higher precision and reliability, meeting the stringent quality standards required by the electronics industry.In addition to its advanced manufacturing capabilities, {Company Name} is committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing process, ensuring that its PCBA products are produced in a sustainable and environmentally responsible manner.With the launch of its latest generation of PCBA, {Company Name} aims to further solidify its position as a leading provider of electronic assembly solutions. The company's dedication to innovation and quality, combined with its commitment to sustainability, sets it apart as a trusted and reliable partner for businesses looking for high-quality PCBA solutions.{Company Name} is also focused on providing exceptional customer service, offering comprehensive technical support and personalized solutions to meet the unique needs of its clients. The company's team of experienced engineers and technicians are dedicated to delivering the highest level of service, ensuring that customers receive the best possible PCBA solutions for their specific requirements.As the demand for advanced electronic devices continues to grow, {Company Name} is well-positioned to meet the needs of the industry with its latest generation of PCBA. The company's commitment to innovation, quality, and sustainability, combined with its exceptional customer service, makes it a top choice for businesses seeking reliable and efficient electronic assembly solutions.In conclusion, {Company Name}'s latest generation of PCBA represents a significant advancement in electronic assembly technology, offering customers a reliable and efficient solution for their electronic manufacturing needs. With its dedication to innovation, quality, and sustainability, {Company Name} is poised to continue leading the industry in providing high-quality PCBA solutions to a wide range of industries.

BGA PCB Assembly: What You Need to Know for Your Electronic Devices

Bga Pcb Assembly Technology Revolutionizes Electronic ManufacturingIn today's rapidly advancing technological landscape, electronic manufacturing companies are constantly seeking innovative ways to enhance the quality and efficiency of their products. One of the most recent breakthroughs in this field is the introduction of BGA PCB assembly technology, which promises to revolutionize the way electronic components are manufactured and integrated into devices.BGA, or Ball Grid Array, is a type of surface-mount packaging used for integrated circuits. It has become increasingly popular in electronic manufacturing due to its high pin count and compact size, which allows for more complex and densely-packed electronic devices. The BGA packaging also offers better thermal and electrical performance, making it an attractive choice for manufacturers looking to enhance the reliability and performance of their products.One company at the forefront of this BGA assembly technology is {}. Established in 2005, {} has been a leading provider of electronic manufacturing services, specializing in PCB assembly, BGA assembly, and other advanced technologies. With a focus on delivering high-quality, cost-effective solutions, {} has become a trusted partner for companies seeking to elevate their electronic manufacturing capabilities.The integration of BGA assembly technology into {}'s manufacturing processes has significantly enhanced the company's ability to produce intricate and high-performance electronic components. By utilizing state-of-the-art BGA assembly equipment and expertise, {} is able to meet the increasing demands for smaller, more powerful electronic devices in a wide range of industries, including telecommunications, medical devices, aerospace, and consumer electronics.One of the key advantages of BGA PCB assembly is its ability to accommodate a higher density of interconnects, leading to a more compact and efficient design. This is particularly important in industries where space is a premium, such as mobile devices and wearables. By leveraging BGA assembly technology, {} is able to offer its clients sophisticated, miniaturized electronic components without compromising on performance or reliability.Furthermore, BGA assembly technology also allows for improved thermal management and electrical integrity, resulting in electronic components that are more durable and robust. This is critical in applications where electronic devices are subjected to harsh environmental conditions or prolonged use. {}'s expertise in BGA assembly ensures that the electronic components they manufacture meet the highest standards of quality and reliability, further solidifying their reputation as a leader in the electronic manufacturing industry.In addition to the technical benefits of BGA PCB assembly, {}'s adoption of this advanced technology has also resulted in streamlined manufacturing processes and reduced production costs. By optimizing the use of space and materials, {} is able to increase production efficiency and yield, ultimately delivering cost savings to their clients without compromising on quality.Looking towards the future, {} remains committed to staying at the forefront of electronic manufacturing innovation. With the continued advancement of BGA assembly technology and other cutting-edge manufacturing techniques, {} is well-positioned to meet the evolving demands of the industry and exceed the expectations of their clients.In conclusion, the integration of BGA PCB assembly technology has propelled {} to the forefront of electronic manufacturing, enabling them to produce smaller, more powerful, and more reliable electronic components. With a track record of innovation and excellence, {} continues to set the standard for electronic manufacturing services, meeting the needs of a diverse range of industries and driving the next wave of technological evolution.

Top 5 Benefits of Using a Metal PCB Board for Your Electronics

Metal PCB Board: A New Breakthrough in Electronic Manufacturing[Company Name], a leading electronic manufacturing company, has announced the development of a groundbreaking new product - Metal PCB Board. This revolutionary new technology is set to transform the electronic manufacturing industry and open up a world of possibilities for high-performance electronic devices.The Metal PCB Board is a game-changer in electronic manufacturing, offering a range of benefits and advantages over traditional PCBs. The use of metal as the base material for the board provides superior thermal performance, excellent heat dissipation, and enhanced mechanical strength. This means that electronic devices using Metal PCB Boards will be able to operate at higher temperatures, have improved reliability and longevity, and be more resistant to physical and environmental stresses.The innovative Metal PCB Board is set to revolutionize the design and production of a wide range of electronic devices, including but not limited to LED lighting, power supplies, automotive electronics, and industrial control systems. With its superior thermal and mechanical properties, the Metal PCB Board is well-suited for applications requiring high power, high frequency, and high reliability.[Company Name]’s Metal PCB Board is also designed to meet the growing demand for smaller and more compact electronic devices. The use of metal as the base material allows for the creation of thinner PCBs, enabling the production of smaller and lighter electronic products. This will be particularly beneficial for the development of portable electronics, wearables, and other miniaturized devices.In addition to its physical properties, the Metal PCB Board offers improved electrical performance. The use of metal as the base material reduces skin effect and dielectric loss, resulting in lower signal distortion and enhanced signal integrity. This makes the Metal PCB Board ideal for high-speed and high-frequency applications, such as telecommunications, data communications, and advanced electronics.With the introduction of Metal PCB Board, [Company Name] is solidifying its position as an industry leader in electronic manufacturing. The company is committed to delivering innovative and high-quality solutions to meet the evolving needs of the electronic industry. The development of Metal PCB Board is a testament to [Company Name]’s dedication to pushing the boundaries of electronic manufacturing and driving forward technological advancements.The Metal PCB Board is the result of extensive research and development efforts by [Company Name]’s team of skilled engineers and scientists. Leveraging years of expertise and experience in electronic design and manufacturing, the company has successfully developed a cutting-edge technology that will have a far-reaching impact on the industry.As a company at the forefront of electronic manufacturing, [Company Name] is dedicated to providing its customers with the most advanced and reliable solutions. The Metal PCB Board is a testament to the company’s commitment to innovation, quality, and customer satisfaction. By offering this groundbreaking technology, [Company Name] is empowering its customers to create electronic products that are more efficient, durable, and high-performing.In conclusion, the introduction of Metal PCB Board by [Company Name] represents a significant advancement in electronic manufacturing. This innovative technology promises to elevate the performance, reliability, and design flexibility of electronic devices across a wide range of industries. With its strong thermal, mechanical, and electrical properties, Metal PCB Board is set to become the material of choice for the next generation of high-performance electronic products. As [Company Name] continues to push the boundaries of electronic manufacturing, the industry can expect to see even more groundbreaking developments in the near future.